Waste Combustion Systems

Our society's trash and waste continues to increase in complexity and quantity. Plastics and other synthetic materials which resist natural decomposition create a greater threat to the environment and therefore place an increased liability on the waste generator. The treatment of trash and waste through advanced technologies is a logical approach to limit cost and liability, but the gasification and combustion process must be safe and controlled to meet today's stringent air quality regulations.

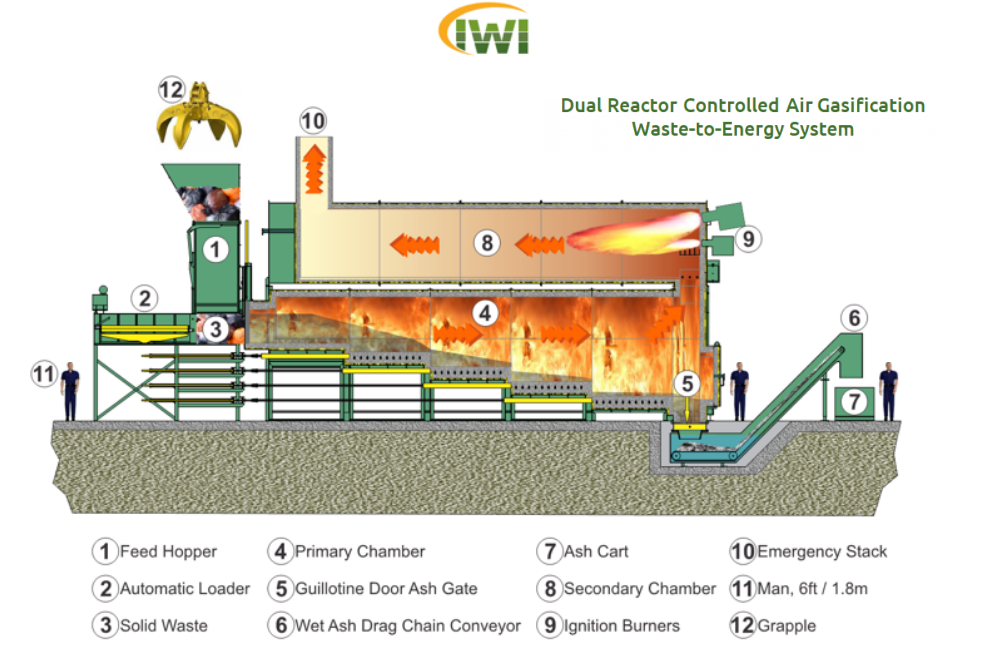

IWI offers a proven solution to cost effective waste disposal and renewable energy - the IWI Dual Reactor Controlled Air Gasification System. These units have been successfully used by health care facilities, industrial facilities, research facilities, institutions, municipalities and commercial operations throughout the world.

How the IWI Dual Reactor Controlled Air Gasification System Works

The IWI system utilizes a two-stage combustion process. In the first stage, waste is converted into combustible gases through a controlled air gasification process. In the second stage, these gases are ignited and fully combusted through the oxidation process.

The two-stage process enables the Dual Reactor System to destroy a wide variety of materials in a non-polluting manner. Gasification is the thermal decomposition of waste in an oxygen-controlled atmosphere. Moisture and hydrocarbons are driven off leaving only a small amount of dry sterile ash.

As waste is fed into the primary chamber of the Dual Reactor System, it is exposed to very high temperatures. The thermal degredation of a small portion of the waste with a controlled quantity of air flowing up through the bed of trash produces the desired operating conditions. Unlike conventional incinerators, air velocities in the primary chamber are very low, thereby minimizing ash disturbance and particulate carryover. The converted gases are ducted to the secondary chamber.

The unique Dual Reactor System secondary chamber combines additional combustion air with the converted gases, creating a vortex action. As the gases begin to mix, positive ignition occurs resulting in complete combustion of all hydrocarbons. The combined effect of optimum turbulence, correct temperature, and adequate retention time insures maximum combustion efficiency.

For optimal performance an Air Pollution Control System can be added to any of our systems.

The process is fully automated and minimizes the requirement of an operator being in attendance to oversee the complete cycle once in progress. Throughout the process the IWI HMI Control System ensures that consistent, thorough and the cleanest possible thermal treatment results are achieved.